I never leave the scope on with the door closed. The cabinet itself is screwed to the shelf so that in case of an impact, it won’t hit the equipment inside.Īs for ventilation, there is 2 inch clearance at the top and 5 inch behind which is not ideal, but good enough. It is a place specially designed so that readers can go there to work on an electronic project, such as testing components, troubleshooting a device, or building a new project. The door frame is made from 2x1 pine strips with a groove in the middle to fit the 3/16 inch thick lexan sheet. The Electronics Workbench was created to assist the newcomer to the field of practical electronics through the creation of a personal electronics workbench.

simulate their Analog, and Digital circuit assignments prior to actual building.

#BUILD YOUR OWN ELECTRONIC WORKBENCH WINDOWS#

It’s made from 3 pieces of 12 inch wide, 3/4 inch thick plywood. version of Electronic Workbench for Windows (EWB 4.0) is a user friendly. BUILD IT WITH TOM AND SAVE Build Your Own Electronics Workshop gives you clear, illustrated directions for making many of the components for your shop yourself, including: Workbench Function/Signal. It measures 23 1/2” long x 8” high by 12 3/4” deep. Build many of the pieces of equipment you need yourself, if you choose Discover the possibilities of circuit-board-design and CAD/CAM software. There’s nothing too fancy here, it’s just a box with a door.

There was always the possibility that I would lose my grip on the piece i’m drilling and that it goes flying towards the LCD screen, not a good thing… That’s why i decided to build this cabinet before something catastrophic happens. Up until now, each time i was using the drill, I always put something over my scope to protect it, but that was not enough. With the drill press this close to my oscilloscope, there is a high risk of debris flying into the vents, especially when i’m drilling aluminum. I installed ball bearing slides instead of the cheap tracks I had before. I Built a frame for them with 2x2’s and painted it black. As it turns out, it fitted perfectly on the side of the storage shelf near my workbench.

#BUILD YOUR OWN ELECTRONIC WORKBENCH INSTALL#

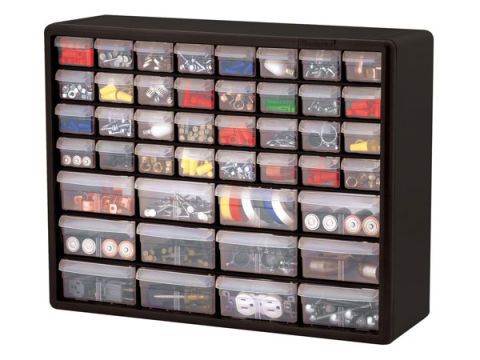

There was no practical places to install drawers for my tools. The frame of the top section is held in place on those legs with two bolts on each sides. The legs on the back extends 12 inch from the top of the work surface.

That is why I made the top section detachable so the whole thing would be easier to move. Now, anyone who had to move a refrigerator down the stairs in a three story apartment building knows how much fun it is. There are two 32 inches wide adjustable shelves on the right side and one fixed shelf on the top which spans the entire width of the workbench. The Path workbench is used to produce machine instructions for CNC machines from a. The top section is 41 inch high and has a perforated board backing (Peg board). Our goal is to build a resource, the CAD user can use as the go-to. I designed the shelves to be part of the workbench itself so I wouldn’t have to drill holes in the wall to hang them.

0 kommentar(er)

0 kommentar(er)